Fisher Steel-Caster Hopper Spreader

Worth Its Salt

When it comes to engineering excellence, small details can make a big difference in the efficiency and profitability of your de-icing activity. The low-maintenance, rust-resistant STEEL-CASTER™ stainless steel hopper spreader was designed to maximize material control and minimize waste. With dual electric motors and enhanced variable-speed control the STEEL-CASTER hopper spreader is available in six sizes for pickup, dump body and flatbed trucks. Gas and hydraulic options also available.

For Best Pricing and Availability

Features, Advantages, and Benefits

- Multiple capacities and length

- Multiple motor types

- Dual electrical uses multiplex system

- Innovative chute design

- Standard features

- Easy to incorporate accessories

- Designed to be scalable for future upgrades

- Price

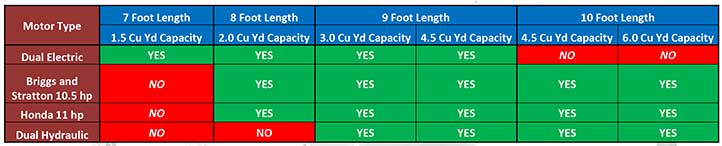

Hopper - Models

- 4 Hopper Lengths - 7', 8', 9' and 10'

- 5 Hopper Capacities - 1.5, 2.0, 3.0, 4.5, and 6.0 cu yd

- 2 Drives - Dual Electric, Dual Hydraulic

Hopper - Standard Features

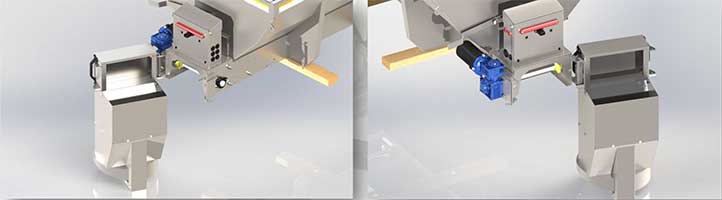

Hopper - Swing Away Chute

- Dual Swing Away Chute Design

- Swings both to the DS or PS

- Tool free chute removal

- Allows easy dumping or filling, for example, a walk behind spreader.

- Chute extension (standard feature)

- Tall and short configuration

- Easy Adjustment - Tools required

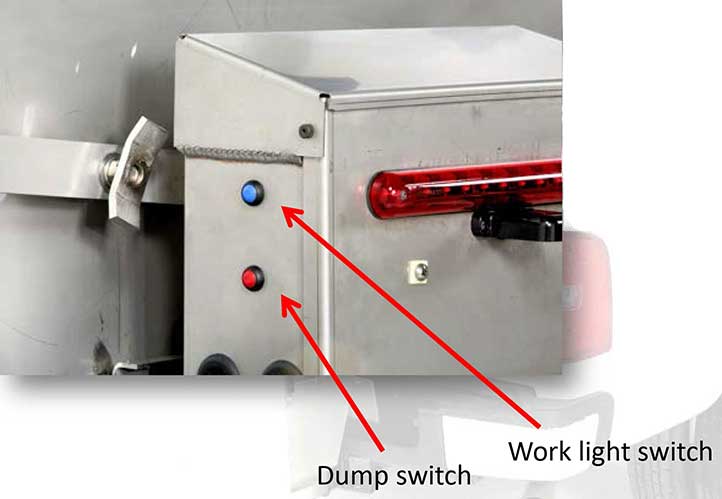

- Rear Dump & Light Switch

- Electric Models Only

- Allows users to feed material from hopper into a walk behind spreader (for example) or to empty hopper for rear

- Activate lighting while at the rear of unit, without having to return to the cab

Hopper - Control

Hopper - Accessory Hub

- Accessory Hub

- "Plug 'n' Play" functionality

- Isolated location (above chute) to prevent corrosion

- Makes accessory installation much easier!

- Uses a multiplex module similar but not identical to the poly hopper

- Integrated "accessory Hub"

- Plug 'n' Play functionality - 6 accessories, including dedicated plugs for a vibrator, 2 work lights, and strobe lights

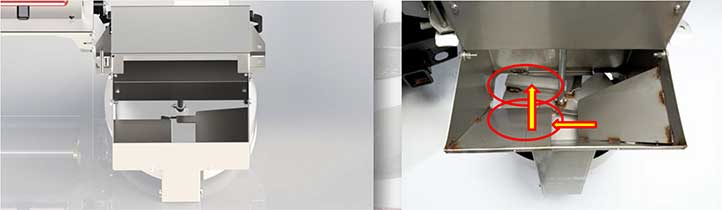

Hopper - Chute Design

- Exceptional spread pattern

- Adjustable deflector

- Reduced material waste innovation

- Complete material control/deflection

- Swing-Away/Tool-less removal

- Chute Baffle Design

- Maximize material usage and reduce waste

- Direct material flow through the chute and onto the spinner in two predetermined quadrants of the spinner - Passenger side front and rear

- Disperse material behind and away from the truck instead of towards and under the truck

Hopper - Shutter Deflector

- Circular shutter housing design that is much more effective than traditional chute designs. (Reduces material spill off the circular spinner)

- The shutter deflector design rotates within the housing to help keep material on the spinner and directed where the operators intends